Stephen Shaler – Research

Engineered wood composites are an increasingly important material for residential and light industrial construction. They can be made in a variety of ways and utilize many combinations of materials. They provide an efficient, low energy, and sustainable material option for building structures. My research incorporates both an engineering and a materials perspective on the manufacture and performance of strand-based and wood plastic composites.

Steam Injection Pressing of Extracted Wood Strands

(Funding: USDA – Wood Utilization Research) : Completed

All research to date evaluating the manufacture of OSB from extracted strands has used conventional heated platen pressing. The impact of pressing with steam has not been determined. Steam is used exclusively for the production of thick composites including laminated strand lumber (LSL) products due to the decreased cycle time and the ability to obtain a flat density profile. This project evaluates whether the use of steam injection pressing changes the performance of strand composites made from hemicellulose extracted wood relative to that obtained using platen pressing.

Dynamic Visualization of Strand Composite Processes

(Funding: USDA McIntire-Stennis Program) : Completed

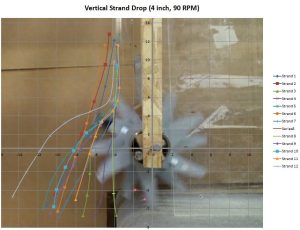

The focus of the wood composite modeling literature on the ultimate product performance is natural and of high importance. However, there is an entire other class of questions involved in the manufacture of wood composites which has been totally ignored. Specifically, the modeling of the dynamic interactions of strands and the processing equipment (e.g.the role of conveyors in uniformly loading of forming bunkers, the dynamic interactions between the strands and forming disks, the bouncing of first-laid strands from the forming belt, etc). These are all examples of dynamic interactions between strands and equipment which influence the final composite structure prior to press consolidation. These kinematic processes (assumed to create a random and homogenous distribution of strands) have their own highly important impact during plant design and operations. The class of problem to be solved in this research can be classified as being in the field of physically based animation in computer graphics

The dynamics of strands in the structural oriented strand composites manufacturing process and their effects on production

(Funding: Wood Based Composites Center) : Completed

The scope of this research is the study of the dynamics, or movement, of strands in the oriented strand composites (OSC) manufacturing process; specifically from the forming bunker to where the strands drop through the orienting deck. This research is being conducted to gain knowledge and to gather data for statistical modeling of the process.

Durability of Wood Plastic Composites for Structural Applications

(Funding: FHWA) : Completed

The long-term behavior (viscoelastic and mechano-sorptive) of WPC’s which will be used in environments involving prolonged moisture exposure must be accounted for in the specification and design process. However, given the potential for formulation modifications including wood amount, UV stabilizer and anti-fungal additives, polymer type, and reinforcement amount – it is clearly not feasible that full-scale long-term structural evaluations be performed for screening.

The need then is to develop and employ short term processes to screen and predict long-term performance as WPC formulations are modified to obtain necessary durability, physical, and mechanical properties.