Laboratory of Renewable Nanomaterials (LRN)

Established in September 2013, the Laboratory of Renewable Nanomaterials (LRN) focuses on alternative applications of cellulose nanomaterials with a special focus on large-volume production and end uses. Dr. Mehdi Tajvidi leads the LRN research group currently consisting of one Assistant Research Professor and six graduate students. LRN has so far attracted over $4M in grant funding to advance the science and technology of renewable nanomaterials. Dr. Mehdi Tajvidi, the director of LRN, is the recipient of the inaugural TAPPI Nanotechnology Mid-Career Award in June 2018.

Current lab members:

Group Leader:

Assistant Research Professor:

Islam Hafez

Postdoctoral Associates:

Mohammad Tauhiduzzaman

Ph.D. Students:

- Wenjing Sun

- Md. Musfiqur Rahman

Master’s Students:

- Justin Crouse

- Md. Ikramul Hasan

- Rakibul Hossain

- Alex Collins

Visiting students:

N/A

Past members:

- Zahra Naghizadeh, visiting Ph.D. student

- Seyyed Mohammad Hashemi Najafi

- Allie Rowe, REU student 2015

- Weiqi Leng, Postdoctoral Associate

LRN members as of May 2016 - Drew Horseman, REU student 2016

- Niloofar Yousefi, Master’s student

- Cherif Diop, Postdoctoral Research Associate

- Michelle Zheng, REU student 2017

- Seyyed Mohammad Mazhari, visiting Ph.D. student

- Colin Noonan, REU student 2018

- Alina Gonzalez-Ugarte, REU student 2019

- Syeed Saifulazry, visiting scientist, INTROP, Universiti Putra Malaysia

- Ali H. Tayeb, Postdoctoral Research Associate

- Shokoofeh Ghasemi, Ph.D. student and Postdoctoral Research Associate

- Ezatollah Amini, Ph.D.

Lab equipment:

- TA Instruments TGA Q500

- Kruss Mobile Surface Analyzer

- ezAFM Atomic Force Microscope

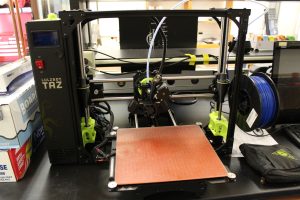

- Taz 6 3D Printer

- 3D Potter Slurry Printer

- Peter Pugger Pug Mill

- Carver Hot Press

- HarvestRight Scientific Freeze Dryer

- Thinky Planetary Mixer

- AmScope Polarized Light Microscope

- Moisture Analyzer

- BYK Automatic Film Applicator

- Sonifier

- Shop Press

- Specimen Table Saw

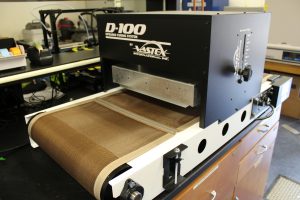

- Infrared IR Conveyor Dryer

- Mocon OXTRAN Oxygen Transmission Analyzer

- TA Instruments Fox 50 Thermal Conductivity Analyzer

- Sound Absorption Analyzer

- 500N Instron Testing Machine (tensile, flexural, comprssion)

Recent Publications/presentations by LRN members:

Peer-reviewed articles:

- Alrubaie, M. A. A., Lopez-Anido, R. A., Gardner, D. J., Tajvidi, M., & Han, Y. 2020. Experimental investigation of the hygrothermal creep strain of wood–plastic composite lumber made from thermally modified wood. Journal of Thermoplastic Composite Materials, 33(9), 1248-1268.

- Amini, E., Hafez, I., Tajvidi, M., & Bousfield, D. W., 2020. Cellulose and lignocellulose nanofibril suspensions and films: A comparison. Carbohydrate Polymers, 117011.

- Wang, L., Gardner, D. J., Wang, J., Yang, Y., Tekinalp, H. L., Tajvidi, M., … & Ozcan, S., 2020. Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships. Composites Part B: Engineering, 108297.

- Alrubaie, M. A. A., Lopez-Anido, R. A., Gardner, D. J., Tajvidi, M., & Han, Y., 2020. Modeling the hygrothermal creep behavior of wood plastic composite (WPC) lumber made from thermally modified wood. Journal of Thermoplastic Composite Materials, 33 (8), 1109-1124.

- Zhao, X., Li, K., Wang, Y., Tekinalp, H., Larsen, G., Rasmussen, D., Ginder, R., Wang, L., Gardner, D.J., Tajvidi, M. and Webb, E., 2020. High-strength polylactic acid (PLA) biocomposites reinforced by epoxy-modified pine fibers. ACS Sustainable Chemistry & Engineering.

- Amini, E., & Tajvidi, M., Mechanical and thermal behavior of cellulose nanocrystals-incorporated Acrodur® sustainable hybrid composites for automotive applications. Journal of Composite Materials, 0021998320912474.

- Wang, L., Chen, C., Wang, J., Gardner, D. J., & Tajvidi, M., Cellulose nanofibrils versus cellulose nanocrystals: Comparison of performance in flexible multilayer films for packaging applications. Food Packaging and Shelf Life, 23, 100464.

- Hafez, I., Amini, E., & Tajvidi, M., 2020. The synergy between cellulose nanofibrils and calcium carbonate in a hybrid composite system. Cellulose, 1-15.

- Tayeb, A.H., Tajvidi, M., & Bousfield, D., 2020. Based Oil Barrier Packaging using Lignin-Containing Cellulose Nanofibrils. Molecules, 25(6), 1344.

- Hafez, I., & Tajvidi, M., Laminated Wallboard Panels Made with Cellulose Nanofibrils as a Binder: Production and Properties. Materials, 13(6), 1303.

- Ghasemi, S., Rahimzadeh-Bajgiran, P., Tajvidi, M., & Shaler, S. M., 2020. Birefringence-based orientation mapping of cellulose nanofibrils in thin films. Cellulose, 27(2), 677-692.

- Najafi, S. M. H., Bousfield, D. W., & Tajvidi, M. Evaluation of the adhesion performance of latex-starch mixtures to calcium carbonate surfaces. Nordic Pulp & Paper Research Journal, DOI: https://doi.org/10.1515/npprj-2018-0083

- Zheng, M., Tajvidi, M., Tayeb, A. H., & Stark, N. M., 2019. Effects of bentonite on physical, mechanical and barrier properties of cellulose nanofibril hybrid films for packaging applications. Cellulose, 26(9), 5363-5379.

- Wang, L., Palmer, J., Tajvidi, M., Gardner, D. J., & Han, Y., 2019. Thermal properties of spray-dried cellulose nanofibril-reinforced polypropylene composites from extrusion-based additive manufacturing. Journal of Thermal Analysis and Calorimetry, 136 (3), 1069-1077.

- Sun, W., Tajvidi, M., Hunt, C. G., McIntyre, G., & Gardner, D. J. 2019. Fully Bio-Based Hybrid Composites Made of Wood, Fungal Mycelium and Cellulose Nanofibrils. Scientific Reports, 9(1), 3766.

- Najafi, S. M. H., Bousfield, D. W., & Tajvidi, M. Cracking at the fold in double layer coated paper: the influence of latex and starch composition. TAPPI JOURNAL, 18(2), 93-99.

- Noonan, C., Tajvidi, M., Tayeb, A. H., Shahinpoor, M., & Tabatabaie, S. E. 2019. Structure-Property Relationships in Hybrid Cellulose Nanofibrils/Nafion-Based Ionic Polymer-Metal Composites. Materials, 12(8), 1269.

- Tayeb, A., Amini, E., Ghasemi, S., & Tajvidi, M., Cellulose Nanomaterials—Binding Properties and Applications: A Review. Molecules, 23(10), 2684.

- Tayeb, A., & Tajvidi, M. (2018). Sustainable Barrier System via Self-assembly of Colloidal Montmorillonite and Crosslinking Resins on Nanocellulose Interfaces. ACS Applied Materials & Interfaces, 11 (1), 1604-1615

- Mashkour, M., Kimura, T., Mashkour, M., Kimura, F., & Tajvidi, M., 2018. Printing Birefringent Figures by Surface Tension-Directed Self-Assembly of a Cellulose Nanocrystal/Polymer Ink Components. ACS Applied Materials & Interfaces, 11(1), 1538-1545.

- Ghasemi, S.*, Tajvidi, D. J., Gardner, D. W. Bousfield & S. M. Shaler. Effect of wettability and surface free energy of collection substrates on the structure and morphology of dry-spun cellulose nanofibril filaments. Cellulose, DOI 10.1007/s10570-018-2029-3.

- Najafi, S. M. H., Tajvidi, M., & Bousfield, D. W. 2018. Production and mechanical characterization of free-standing pigmented paper coating layers with latex and starch as binder. Progress in Organic Coatings, 123, 138-145.

- Mousavi, S. M. M., Afra, E., Tajvidi, M., Bousfield, D. W., & Dehghani-Firouzabadi, M., 2018. Application of cellulose nanofibril (CNF) as coating on paperboard at moderate solids content and high coating speed using blade coater. Progress in Organic Coatings, 122, 207-218

- Ghasemi, S., Tajvidi, D.W. Bousfield and D. J. Gardner, 2018. Reinforcement of natural fiber yarns by cellulose nanomaterials: A multi-scale study. Industrial Crops and Products, 111, 471-481.

- Wang, Lu, W.M. Gramlich, D.J. Gardner, Y. Han and Tajvidi, 2018. Spray-dried cellulose nanofibril-reinforced polypropylene composites for extrusion-based additive manufacturing: nonisothermal crystallization kinetics and thermal expansion. Journal of Composites Science, 2(1), 7.

- Wang, J., D. J. Gardner, N. M. Stark, D. W. Bousfield, Tajvidi, and Z. Cai, 2017. Moisture and oxygen barrier properties of cellulose nanomaterial-based films. ACS Sustainable Chemistry & Engineering, 6(1), 49-70.

- Fraver, S., Tajvidi, A.W. D’Amato, D. L. Lindner, J.A. Forrester and A.M. Milo, 2017. Woody material structural degradation through decomposition on the forest floor. Canadian Journal of Forest Research, 48(1), 111-115.

- Naghizadeh Mahani, Z. and Tajvidi, 2017. Viscoelastic mapping of spruce- polyurethane bond line area using AM-FM atomic force microscopy. International Journal of Adhesion and Adhesives, 79, 59-66.

- Diop, C. I. K., Tajvidi, M. A. Bilodeau, D. W. Bousfield & J. F. Hunt, 2017. Evaluation of the incorporation of lignocellulose nanofibrils as sustainable adhesive replacement in medium density fiberboards. Industrial Crops and Products: 109, 27-36.

- Hunt, J. F., W. Leng, and Tajvidi, 2017. Vertical density profile and internal bond strength of wet-formed particleboard bonded with cellulose nanofibrils. Wood and Fiber Science, 49(4), 1-11.

- Davids, W. G., N. Willey, R. Lopez-Anido, S. Shaler, D. Gardner, R. Edgar & Tajvidi, (2017). Structural performance of hybrid SPFs-LSL cross-laminated timber panels. Construction and Building Materials, 149, 156-163.

- Leng, W., J. F. Hunt, & Tajvidi, 2017. Screw and Nail Withdrawal Strength and Water Soak Properties of Wet-formed Cellulose Nanofibrils Bonded Particleboard. BioResources, 12(4), 7692-7710.

- Ghasemi, S., Tajvidi, D. W. Bousfield, D. J. Gardner & W. M. Gramlich, 2017. Dry-Spun Neat Cellulose Nanofibril Filaments: Influence of Drying Temperature and Nanofibril Structure on Filament Properties. Polymers, 9(9), 392.

- Diop, C. I. K., Tajvidi, M. A., Bilodeau, D. W. Bousfield, & J. F Hunt, 2017. Isolation of lignocellulose nanofibrils (LCNF) and application as adhesive replacement in wood composites: example of fiberboard. Cellulose, 24(7), 3037-3050.

- Amini, E., Tajvidi, D. J. Gardner & D. W. Bousfield (2017). Utilization of Cellulose Nanofibrils as a Binder for Particleboard Manufacture. BioResources, 12(2), 4093-4110.

- Leng, W., J. F. Hunt, & Tajvidi, 2017. Effects of Density, Cellulose Nanofibrils Addition Ratio, Pressing Method, and Particle Size on the Bending Properties of Wet-formed Particleboard. BioResources, 12(3), 4986-5000.

- Mousavi, S. M., E. Afra, Tajvidi, D. W. Bousfield, & M. Dehghani-Firouzabadi, 2017. Cellulose nanofiber/carboxymethyl cellulose blends as an efficient coating to improve the structure and barrier properties of paperboard. Cellulose, 24(7), 3001-3014.

- Horseman, T., Tajvidi, Diop, C.I.K and D.J. Gardner, 2017. Production and property assessment of neat lignocellulose nanofibrils (LCNF) and their composite films. Cellulose. 24 (6), 2455-2468.

- Yousefi Shivyari, N., Tajvidi, D. Gardner and D. Bousfield, 2016. Production and characterization of laminates of paper and cellulose nanofibrils. ACS Applied Materials and Interfaces, 8(38): 25520-25528.

- Rowe, A., Tajvidi and D.J. Gardner, 2016. Thermal stability of cellulose nanomaterials and their composites with polyvinyl alcohol (PVA). Journal of Thermal Analysis and Calorimetry. 126 (3): 1371-1386.

- Gardner, D. J. and Tajvidi, 2016. Hydrogen bonding in wood-based materials: an update. Wood and Fiber Science. 48 (4): 234-244.

- Tajvidi, M., D. J. Gardner and D. Bousfield, 2016. Cellulose Nanomaterials as Binders: Laminate and Particulate Systems. Journal of Renewable Materials. 4 (5): 365-376.

- Rasouli, D., N. Tzankova Dintcheva, M. Faezipour, F.P. La Mantia, M.R. Mastri Farahani and Tajvidi, 2016. Effect of nano zinc oxide as UV stabilizer on the weathering performance of wood-polyethylene composite. Polymer Degradation and Stability 133: 85-91.

- Tajvidi, M. and L. C. Simon, 2015. High temperature creep behavior of wheat straw-isotactic/impact modified polypropylene composites. Journal of Thermoplastic Composite Materials, 28(10) 1406–1422.

- Khonsari, A., H. R. Taghiyari, A., Karimi and Tajvidi, 2015. Study on the effects of wood flour geometry on physical and mechanical properties of wood-plastic composites. Maderas-Cienc Tecnol 17(3):545-558.

- Dastoorian, F., M., Layeghi, G. Ebrahimi, Tajvidi and S.M. Zabihzadeh, 2015. Evaluation of the influence of elevated temperatures on the mechanical properties of a commercial unrefined bagasse fiber-polypropylene composite. Iranian Journal of Wood and Paper Industries, 5(2): 129-142.

Conference Presentations:

- Tajvidi, M., Noonan, C., Tayeb, A.H., Shahinpoor, M and Tabatabaie, S.E., 2019. Ionic Polymer Metal Composites for Sensing and Actuation Produced with cellulose nanomaterials. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Chiba, Japan, June 3-7, 2019.

- Hafez, I. and Tajvidi, M., 2019, Eco- and health-friendly gypsum board substitute based on cellulose nanofibrils (CNF) as a binder. TechConnect World 2019, Boston, MA. June 17-19 2019.

- Gardner, D.J., Tajvidi and Y. Han 2018. Cellulose Nanocomposites: Status of Development from a Commercial Perspective. SPE/ACCE, Novi, MI, September 4-7 2018.

- Tajvidi, M. Facts and myths about cellulose nanofibrils (CNF): what to expect and what to not, TechConnect 2018, Anaheim, CA, USA, May 13-16, 2018.

- Tayeb, A.H., Tajvidi, 2018. Moisture/Oxygen barrier properties of nanocellulose-montmorillonite hybrid films enhanced with cross-linking additives, Forest Products Society 72nd International Convention, Madison, WI, USA, June 11-14, 2018.

- Sun, W. and Tajvidi, 2018. Enhancement of the physical and mechanical properties of mycelium-bonded composite panels by cellulose nanofibrils. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Madison, WI, USA, June 11-14, 2018

- Amini, E. Tajvidi, D.W. Bousfield and D. Gardner, 2018. Cellulose nanofibrils-bonded particleboards: production, property evaluation and dewatering process. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Madison, WI, USA, June 11-14, 2018.

- Tajvidi, M. and M. Zheng, 2018. Structure-property relationships in physical, mechanical and barrier properties of hybrid cellulose nanofibril/bentonite films for packaging applications. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Madison, WI, USA, June 11-14, 2018.

- Ghasemi, S., Tajvidi, D.W. Bousfield, D. Gardner and W. Gramlich, 2018. Dry-spun neat cellulose nanofibril filaments: effect of process variables and additive on filament properties. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Madison, WI, USA, June 11-14, 2018.

- Bousfield, D.W., S. M. Mousavi, Tajvidi and E. Afra, 2018. Comparison of coating methods for the application of cellulose nanofibrils (CNF) as coating on Paperboard. TAPPI International Conference on Nanotechnology for Renewable Nanomaterials, Madison, WI, USA, June 11-14, 2018.

- Amini, E. and Tajvidi, 2017. Effect of adding cellulose nanocrystals (CNC) on the mechanical and thermal behavior of Acrodur® biocomposites. SPE/ACCE, Novi, MI, September 5-8 2017.

- Tajvidi, M. and D.J. Gardner, 2017. Where nano and sustainable meet: opportunities and challenges for automotive applications using cellulose nanomaterials. SPE/ACCE, Novi, MI, September 5-8 2017.

- Mousavi, S. M., E. Afra, Tajvidi, D. W. Bousfield and M. Dehghani-Firouzabadi, 2017. Strength and barrier enhancement of paperboards properties with cellulose nanofibrils applied by blade coater. International Conference on Nanotechnology for Renewable Nanomaterials, Montreal, Canada, June 5-8, 2017.

- Tajvidi, M. and C.I.K. Diop, 2017. Lignocellulose nanofibrils (LCNF) a viable low cost alternative to cellulose nanofibrils in binder applications: effect on physico-mechanical properties of resin-free medium density fiberboards (MDF). International Conference on Nanotechnology for Renewable Nanomaterials, Montreal, Canada, June 5-8, 2017.

- Hashemi Najafi, S. M., Tajvidi and D.W. Bousfield, 2017. Mechanical properties of free standing pigmented coating layers with latex and starch as binder: bending, tensile and picking properties. Papercon 2017, Minneapolis, MN, April 23-26 2017

- Tajvidi, M. and T. Horseman, 2017. Improvement of the physical and mechanical properties of lignocellulose nanofibrils (LCNF) films through hybridization. International Conference on Nanotechnology for Renewable Nanomaterials, Montreal, Canada, June 5-8, 2017.

- Tajvidi, M., W. Leng, J.F. Hunt, C. Diop, D. Bousfield, D. Gardner, E. Amini, M. Bilodeau and W. Gramlich, 2017. Binder applications of cellulose nanofibrils: new developments. TechConnect World Innovation Conference and Exhibition, Washington D.C., May 14-17 2017.

- Tajvidi, M., 2016. Cellulose nanomaterials: production, properties, applications and future prospects. Nanoworld Conference, Boston, MA, April 4-6 2016.

- Tajvidi, M. and Z. Naghizadeh Mahani, 2016. AM-FM Viscoelastic Mapping: applications for nanocomposite mechanical characterization. SPE Polymer Nanocomposites Conference, Bethlehem, PA, October 16-18 2016.

- Mazhari Mousavi, S.M., D. Bousfield, Tajvidi, and E. Afra, 2016. Cellulose nanofibers as a coating material to improve the structure and barrier properties of paperboard. TAPPI Advanced Coating Symposium, Stockholm, Sweden, October 4-6 2016.

- Hashemi Najafi, S.M., Tajvidi and D. Bousfield, 2016. Mechanical properties of free standing coating layers: bending and tensile properties. TAPPI Advanced Coating Symposium, Stockholm, Sweden, October 4-6 2016.

- Tankut, N., M. Zor, Tajvidi, D. J. Gardner, and H. Yazici, 2016. Water absorption and thickness swelling behavior of thermally treated lignocellulosic reinforced styrene maleic anhydride (SMA) composites. 27th International Conference on Wood Science and Technology, University of Zagreb, Croatia, October 13-14 2016.

- Yousefi Shivyari, N., Tajvidi, D.W. Bousfield, and D.J. Gardner, 2016.

Evaluating physical and mechanical properties of cellulose Nanofibril (CNF) bonded paper laminates. SPE Polymer Nanocomposites Conference, Bethlehem, PA, October 16-18 2016. - Tajvidi, M., D. Bousfield and D. Gardner, 2016. Cellulose nanofibrils as binders: applications and adhesion mechanisms. International Conference on Nanotechnology for Renewable Nanomaterials, Grenoble, France, June 13-16 2016.

- Rowe, A., Tajvidi, and D. Gardner, 2016. Thermal degradation kinetics of cellulose nanomaterials and their composites with polyvinyl alcohol (PVA). International Conference on Nanotechnology for Renewable Nanomaterials, Grenoble, France, June 13-16 2016.

- Amini, E., Tajvidi, D.J. Gardner and D.W. Bousfield, 2016. Introduction of cellulose nanofibrils as an adhesive binder for particleboard manufacture. SPE Polymer Nanocomposites Conference, Bethlehem, PA, October 16-18 2016.

- Ghasemi, SH., Tajvidi, D.W. Bousfield, and D.J. Gardner. 2016. Influence of different cellulose nanofibril suspensions on properties of yarns and tapes produced from hemp natural fibers. SPE Polymer Nanocomposites Conference, Bethlehem, PA, October 16-18 2016.

- Yousefi Shivyari, N. and Tajvidi, 2015. All-Renewable Paper Nano-Laminates for Automotive Applications. SPE/ACCE, Novi, MI, September 9-11 2015.

- Ghasemi, Sh. and Tajvidi, 2015. Cellulose Nanoparticle Reinforced Polyurethane Foams. SPE/ACCE, Novi, MI, September 9-11 2015.

- Tajvidi, M. Transparent Composite Films of All-Cellulose and Cellulose-Polyvinyl Alcohol Nanocomposites: Effect of Relative Humidity and Temperature on Mechanical Performance. SPE/ACCE, Novi, MI, September 9-11 2015.

- Tajvidi, M. Cellulose Nanofibril Bound Laminated Paper Nanocomposites (Cellubound). International Conference on Nanotechnology for Renewable Nanomaterials, Atlanta, GA, June 22-25 2015.

- Crouse, J. and Tajvidi, 2015. Temperature and humidity dependent mechanical performance of nanocellulose and its composites. SWST Annual Convention, Grand Tetons National Park, WY, June 7-12 2015.